All growers know the importance of cycles with the growing cycle being the heart of their operation. But there’s another cycle that your dehumidifier goes through that’s crucial to the success of every grow when it comes to environmental control: the defrost cycle. Understanding what happens (and doesn’t happen) during these defrost cycles, as well as the benefits of technologies like Anden’s patented VLGR (Variable-speed, Low Grain Refrigerant), can help you optimize your grow. Here’s why.

Dehumidifiers help create the right environment for your plants by blowing humid air across cool coils to remove excess moisture. However, you may not have known that as temperatures fall, ice can form on those coils. This is especially true when utilizing a dehumidifier that was not designed specifically for indoor cultivation. When ice forms on the coils, your unit will enter its defrost cycle, during which the compressor will turn off while the fan still runs, working to melt and then re-evaporate the ice and water that has collected. At this time, your dehumidifier isn’t effectively removing moisture from your grow room.

That’s exactly why we developed VLGR technology. To help us explain how this cycle can impact your unit and what you can do to make the best use of the time your dehumidifier is resting, we asked Anden Senior Applications Engineer Randy Lenz to answer a few questions for us.

Can you explain how a typical defrost cycle differs from a defrost cycle in the A710 High-Capacity, Grow-Optimized Dehumidifier with VLGR Technology?

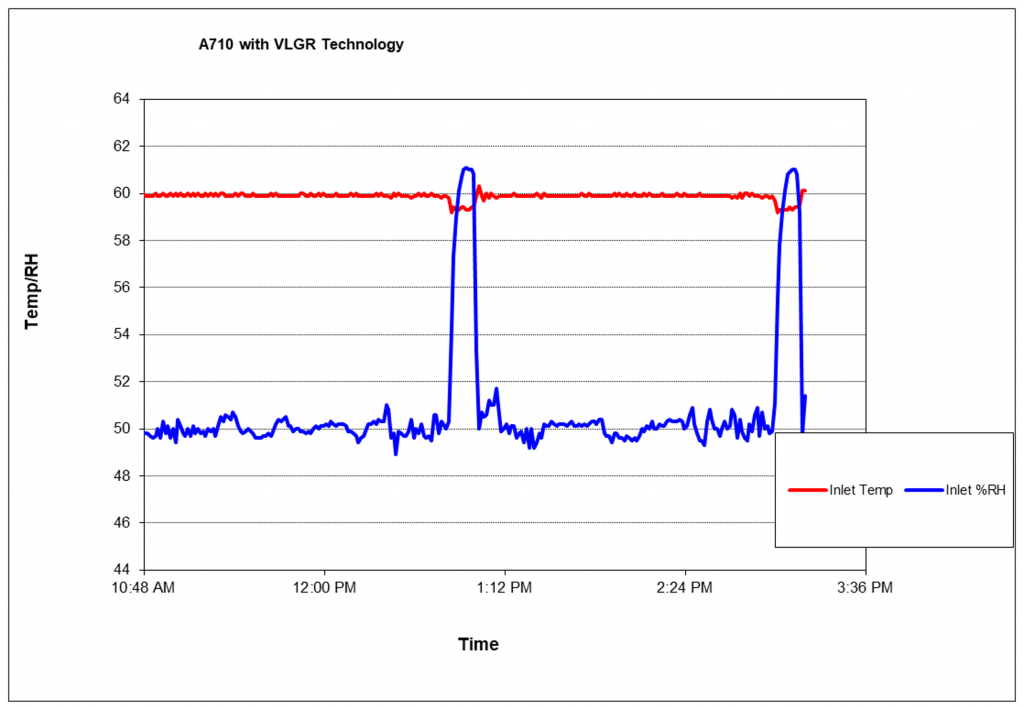

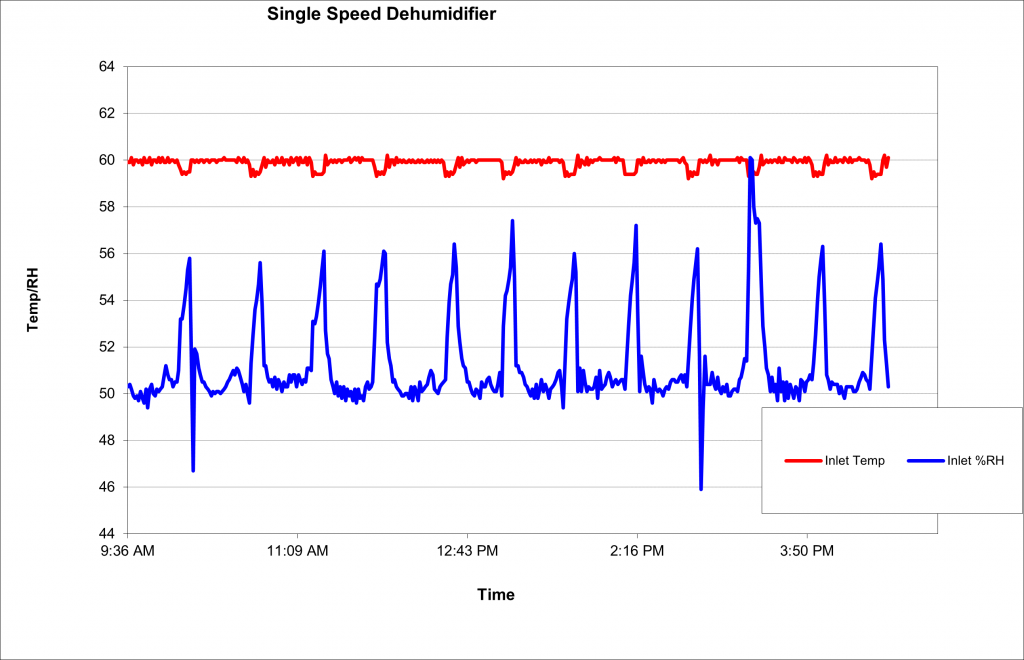

“When a dehumidifier is in defrost, it is not removing any moisture from the air. The goal, therefore, is to avoid defrost cycles by adjusting compressor output to match the load. VLGR technology allows us to experience 10x fewer defrost cycles. This is visible in the charts below where the unit from Anden has only two spikes whereas a single-speed dehumidifier shows many spikes during a 24-hour period in late flower conditions at 60°F and 50% RH.”

How long does a typical defrost cycle last?

“The length of a defrost cycle depends on the ambient environment and how much ice has been allowed to form on the coil. A single-speed dehumidifier will typically build more ice because it cannot modulate the compressor down to avoid over-cooling. Our VLGR technology actively manages compressor output to match the load, meaning far less frequent and short defrost cycles. When a dehumidifier is in defrost, it is not removing any moisture.”

How does VLGR technology function differently, if at all, during different stages of the growing cycle? Does anything need to be adjusted as target RH levels change?

“VLGR technology allows us to modulate the capacity in BTUs of our refrigeration system to ensure that the optimal amount of power is being utilized to efficiently dry the air based on the current load demands.”

Interesting. Can you define BTU for some of our readers?

“The British Thermal Unit (BTU) is a unit of heat. It is defined as the amount of heat required to raise the temperature of one pound of water by one degree of Fahrenheit.”

Many believe that “the best cultivators are trying to simulate Mother Nature.” In what other ways does VLGR technology mimic outdoor growing conditions?

“The A710 with VLGR technology gives the cultivator increased control and the ability to effectively remove moisture across a wider spectrum of operational conditions. Therefore, the A710 with VLGR helps cultivators efficiently and smoothly alter environmental conditions with a higher level of precision, allowing for a tighter simulation of Mother Nature.”

Built for Grow

Anden’s patented VLGR technology allows the A710 dehumidifier to avoid overcooling the coil, which in turn translates to dramatically longer run times and far fewer defrost cycles. With fewer breaks to readjust, your plants will experience a more controlled environment and ideal temperatures.

Know more. Grow more.

Have a question? Need help getting started? Give us a call at 1-800-972-3710 or drop us a line.